Don’t Misuse Ternanry Metal Phosphides: A Common Mistake To Avoid

Understanding Ternanry Metal Phosphides is essential for researchers and engineers working with advanced materials. Ternanry Metal Phosphides offer unique electronic, catalytic, and magnetic properties, but misusing them leads to unreliable results and safety concerns. In this article, we highlight common mistakes to avoid and practical guidelines for correct handling, characterization, and application of Ternanry Metal Phosphides.

What makes Ternanry Metal Phosphides unique

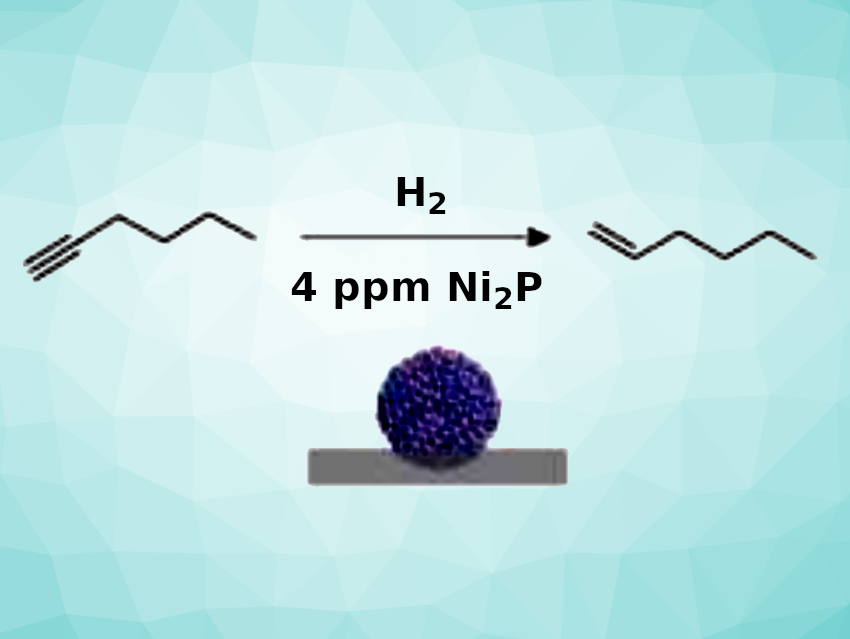

These compounds form complex phase diagrams where composition, crystal structure, and synthesis conditions determine performance. When properly prepared, Ternanry Metal Phosphides can exhibit high catalytic activity, favorable conductivity, and robust thermal stability. Understanding the interplay between metal components and phosphorus is key to leveraging their properties.

Why misuse is a problem

Misusing Ternanry Metal Phosphides often stems from assuming methods that work for other phosphide families will transfer directly. Small errors in temperature, time, or atmosphere can push the material into undesired phases, degrade surface chemistry, or alter electronic structure, leading to misleading performance metrics.

Key Points

- Ternary Metal Phosphides demand precise stoichiometry; small deviations create unwanted phases and reduced performance.

- Moisture and air exposure can rapidly degrade phosphide samples, leading to misleading results.

- Blindly applying protocols from other phosphide systems often fails due to different phase behavior and catalysts.

- Overlooking phase purity and crystal structure can hide active versus inactive species.

- Inadequate safety assessments can overlook phosphide hazards, requiring proper PPE and ventilation.

Practical guidelines to use correctly

To avoid these pitfalls, follow careful preparation and validation steps. Plan experiments with phase diagrams in mind and integrate robust characterization early.

Step 1: Verify the exact metal-to-phosphorus ratio using multiple analytical techniques such as EDS or ICP.

Step 2: Control the atmosphere during synthesis to minimize oxidation and hydrolysis of phosphorus-containing species.

Step 3: Confirm phase purity with X-ray diffraction and assess surface properties with spectroscopy before interpreting activity.

Step 4: Document all parameters to support reproducibility and avoid misguided conclusions in later scaling attempts.

What is the most common mistake people make when working with Ternanry Metal Phosphides?

+The most common misstep is assuming results from one phosphide system transfer directly to another. Differences in phase stability, surface chemistry, and synthesis conditions can lead to misleading conclusions if you don’t tailor parameters to the specific ternary system.

How should I verify the composition and phase purity of my sample?

+Use complementary techniques such as X-ray diffraction for phase identification, electron microscopy for morphology, and chemical assays (ICP/EDS) for stoichiometry. Cross-check results to catch nonstoichiometric impurities that could skew performance data.

What safety precautions are essential when handling Ternanry Metal Phosphides?

+Phosphides can react with moisture producing hazardous byproducts. Work in a well-ventilated area or glovebox when possible, wear appropriate PPE, and store materials under inert atmosphere to minimize exposure and degradation.

Can you provide a quick checklist for evaluating a new Ternanry Metal Phosphide catalyst?

+Yes. Verify phase purity and stability, assess surface chemistry, test under representative conditions, compare with control samples, and document any deviations between predicted and observed activity to guide further optimization.