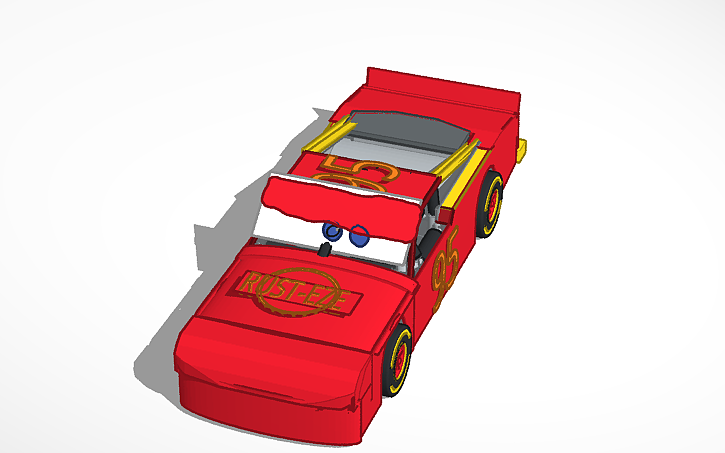

Lightning Mcqueen 3D Model Tinkercad is more than a kid-friendly fantasy—it’s a case study in how careful CAD design and print settings can produce surprisingly fast results. In this article, we explore why this model prints quickly and how you can replicate that speed in your own projects.

Several factors influence print speed, including geometry, layer height, and orientation. The Lightning Mcqueen 3D Model Tinkercad leverages streamlined geometry and minimal supports to shave minutes off build time while still delivering a recognizable and vibrant finish. With typical slicer settings—0.2 mm layer height, efficient wall thickness, and smart infill strategies—you can achieve noticeable time savings without sacrificing the iconic look.

Core design elements that enable fast prints

The design emphasizes clean curves, flat faces, and gentle transitions that reduce support needs and keep tolerances forgiving. Since Tinkercad favors simple shapes, this Lightning Mcqueen 3D Model Tinkercad uses a mix of prisms and rounded profiles to maintain a crisp silhouette while staying printable at higher speeds. Orienting the model to minimize overhangs is a simple but powerful speed hack.

Another key factor is detailing that is impactful yet light. Features like the spoiler, wheels, and headlights can be modeled as separate, lightweight pieces or as shallow shells. This approach allows for faster slicing and printing, while you can still assemble a faithful final model. When combined with a modest layer height and proper cooling, you’ll notice smoother surfaces and quicker layer changes.

Key Points

- The model’s simplified geometry reduces print time without losing the recognizable silhouette.

- Smart orientation minimizes supports and maximizes perimeter efficiency per layer.

- Layer height and shell settings are tuned to prioritize speed over ultra-fine detail.

- Material choice and cooling strategy help maintain consistent print speeds and quality.

- Post-processing steps are streamlined to preserve overall time savings.

Whether you’re a hobbyist, educator, or maker, this Lightning Mcqueen 3D Model Tinkercad example shows how speed and quality can go hand in hand when printability is considered from the start.

What settings maximize speed for the Lightning Mcqueen 3D Model Tinkercad?

+Use a 0.2 mm layer height, 2–3 perimeters, and limited or no infill. Print with moderate acceleration and enable cooling for overhangs; orient the model to minimize supports; aim for a single-piece design when feasible to reduce assembly time.

<div class="faq-item">

<div class="faq-question">

<h3>Can this model be printed in one piece or should it be separated?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>Often you can print as a single piece depending on your printer size and orientation, but breaking it into subassemblies like wheels and spoiler can reduce print time and improve surface finish when needed.</p>

</div>

</div>

<div class="faq-item">

<div class="faq-question">

<h3>Is Tinkercad the only tool to prepare this model?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>While Tinkercad is great for quick edits, you can export to STL/OBJ and fine-tune in slicers like Cura or PrusaSlicer to optimize speed, supports, and layer height.</p>

</div>

</div>

<div class="faq-item">

<div class="faq-question">

<h3>What makes this model a good example of fast printing?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>Its combination of simple geometry, minimal overhangs, and smart part orientation demonstrates how printing speed can coexist with recognizable detail, especially for character replicas used in classrooms or quick showcases.</p>

</div>

</div>