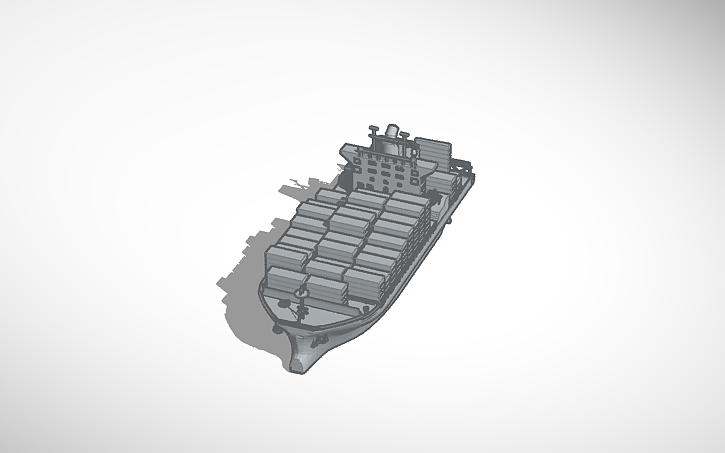

Despite the hype around Cargo Boat Tinkercad, creating a reliable cargo boat model doesn’t have to be complicated. This article breaks down why the myth persists, and shows practical steps to achieve easy, fast, and accurate designs that print well and look professional.

What the Cargo Boat Tinkercad myth gets wrong

Many hobbyists assume that Tinkercad’s simplicity limits nautical models to toy-like results. In reality, the core ideas of scale, modular thinking, and precise alignment apply just as well to cargo boats as to any other project. The myth often stems from rushing through tutorials without validating dimensions or considering real-world constraints like material thickness and printer tolerances.

Practical steps for easy, fast, accurate designs

Start with a clear plan and build in layers. Break the hull into simple shapes, use consistent units (millimeters), and snap to a grid to maintain alignment. Verify fit between sections before adding fillets or textures. By focusing on fundamentals, you can accelerate the design process without sacrificing accuracy.

Key Points

- Establish a fixed scale (for example, 1:50) and lock the units to millimeters to prevent size drift during modeling.

- Use modular blocks (hull, deck, cabins) that align on a shared reference plane to simplify assembly and revisions.

- Leverage Tinkercad's alignment tools to ensure straight edges, true corners, and uniform gaps.

- Validate dimensions with quick measurements and cross-check with simple print-test components before full builds.

- Document tolerances and design intent (wall thickness, fit allowances) to avoid overcomplication while staying accurate.

Design tips to keep it simple

Keep the geometry clean and avoid unnecessary curvature early on. If you’re unsure about a feature, model it as a separate component that can be swapped or scaled later. Regularly export intermediate versions to visualize progress and catch issues before they compound.

How accurate can a Cargo Boat Tinkercad model be for 3D printing?

+Accuracy depends on setting a consistent scale, correct unit selection, appropriate wall thickness, and printer calibration. By validating key dimensions against a real-world reference and printing small test segments, you can achieve reliable results without sacrificing speed.

Is it feasible for beginners to design a cargo boat model quickly in Tinkercad?

+Yes. Beginners benefit from starting with a simple hull silhouette, then adding modular components. Following a step-by-step approach and reusing saved components greatly speeds up the process, turning initial curiosity into a tangible print in a short time.

What are common mistakes that slow you down when using Tinkercad for cargo boats?

+Common slows include overcomplicating shapes, skipping unit checks, neglecting tolerances, and rushing to final details before validating core geometry. Addressing these early keeps the project moving smoothly and reduces rework.

How should I validate the model before printing?

+Use dimensional measurements within the model, export STL for a quick visual check in a slicer, and print a small test hull section to confirm fit and wall thickness. Iterative testing catches issues before committing to a full print run.