Austempered Ductile Iron, or ADI, is a heat-treated alloy renowned for its unmatched combination of toughness and wear resistance. By carefully controlling the austempering process, ADI develops an ausferritic microstructure that delivers high strength without sacrificing ductility, making it a reliable choice for demanding engineering components. In this article, we’ll explore what ADI is, why it excels in toughness and wear resistance, and how to apply it effectively in design and manufacturing.

Key Points

- Ausferritic microstructure in ADI provides a unique balance of high strength, excellent toughness, and good ductility, reducing brittle failure modes.

- Controlled isothermal transformation during austempering yields uniform mechanical properties across complex shapes and thick sections.

- Wear resistance benefits from a refined matrix combined with graphite nodules that minimize surface damage under sliding and impact conditions.

- Machinability remains practical, enabling efficient production of intricate parts without excessive tool wear.

- Fatigue performance is enhanced, making ADI a preferred material for gears, crankshafts, and other high-load components.

What is Austempered Ductile Iron?

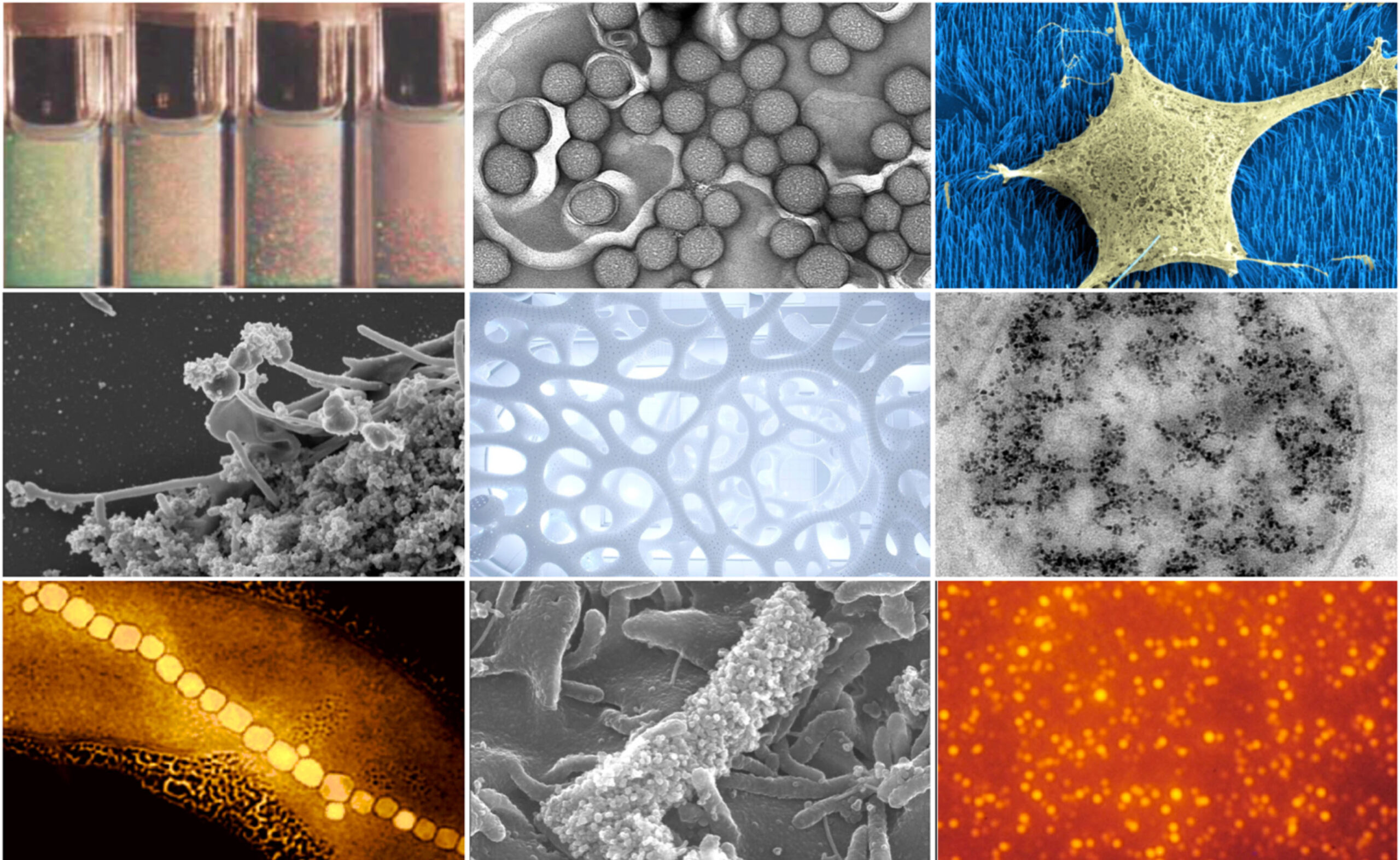

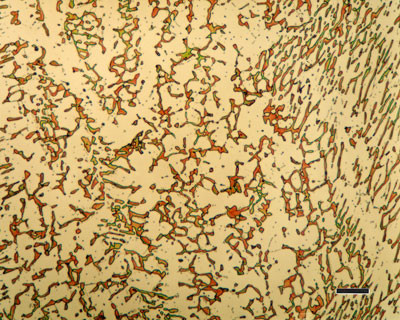

Austempered Ductile Iron (ADI) is produced by an austempering heat treatment that preserves graphite nodules while transforming the matrix into an ausferritic structure. This bainitic-like microstructure combines acicular ferrite with stabilized carbon-rich austenite, yielding a material that is both strong and tough. Unlike traditional ductile iron that relies on pearlite for strength, ADI achieves its performance through controlled phase transformation, resulting in a lighter, more impact-resistant alloy suitable for critical parts.

How Austempering Achieves Toughness and Wear Resistance

The toughness of ADI comes from the ausferritic matrix which absorbs impact energy without fracturing. Wear resistance is enhanced by a hard, yet tough, matrix paired with graphite nodules that act as solid lubricants and crack arresters. This combination reduces surface fatigue and extends component life in high-contact and shock-loading scenarios. Additionally, the austempering window can be tuned to optimize hardness and toughness for specific applications, providing engineers with a versatile design tool.

Industrial Applications and Benefits

ADI is widely used in automotive, industrial, and agricultural equipment where a premium blend of strength, toughness, and wear resistance is needed. Common applications include gears, crankshafts, connecting rods, pump impellers, and valve bodies. The ability to maintain performance across a range of temperatures and loading conditions makes ADI a dependable choice for components exposed to repetitive impacts, high-contact wear, or fatigue-prone environments.

Design Considerations and Processing

To maximize the benefits of Austempered Ductile Iron, engineers select the austempering temperature and soak time to achieve the desired ausferrite fraction and hardness. Alloying elements such as copper, nickel, and molybdenum can tailor toughness, wear resistance, and high-temperature stability. Casting conditions, cooling rates, and post-processing steps all influence microstructure uniformity, so tight process control is essential for consistent performance in mass production.

What is ausferrite, and how does it contribute to ADI's toughness?

+Ausferrite is the bainitic-like microstructure formed during austempering. It combines acicular ferrite with stabilized austenite, delivering a blend of strength, toughness, and wear resistance that suits high-load, impact-prone components without becoming too brittle.

How does ADI compare to conventional ductile iron in wear resistance?

+ADI generally offers superior wear resistance due to its refined ausferritic matrix and stable graphite nodules, which reduce surface damage and friction under sliding and impact conditions. This translates to longer component life in demanding bearing and gear applications.

What are typical applications that benefit most from Austempered Ductile Iron?

+Typical applications include gears, crankshafts, camshafts, pump components, valve bodies, and heavy-duty linkages—parts that require a high combination of toughness, wear resistance, and reliable fatigue performance.

Can ADI be machined and cast easily in high-volume production?

+Yes. ADI is cast using conventional ductile iron foundry practices, and, thanks to its favorable machinability, it supports efficient high-volume production. The austempering process is the main variable, which can be scaled with proper heat-treatment equipment and process control.